|

|

|

|

|

| ■ 位置 > 首页 > 罗德产品 |

|

|

|

|

|

|

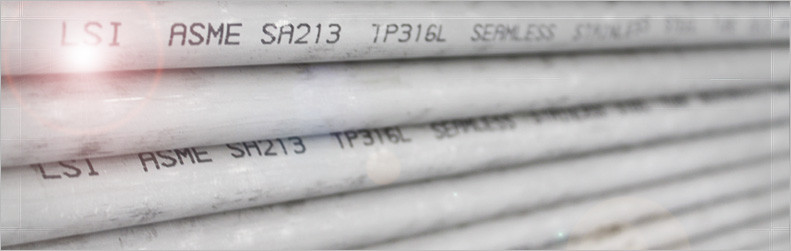

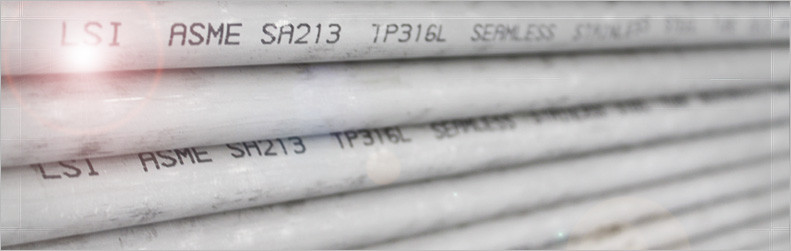

高性能換熱管/冷凝管

熱交換器是諸多工厂生產設備的重要组成部分。随着对运行经济性和安全性越来越重视,从基线检查和环境监测方面所取得的好处是显而易见的。LSI專注於生產高品質的熱換熱管並未我們的客戶提供安全和經濟的熱換熱管解決方案。

|

|

* 核電行業

*化工行業

*石油化工行業

*加熱通風設備空調,冷卻裝置

*食品和啤酒製造

* 發電廠 |

| |

|

|

|

高性能換熱管/冷凝管 (奧氏體不鏽鋼) |

| ASTM/ASME |

JIS |

En |

DIN |

C |

Cr |

Ni |

Mo |

N |

Others |

Remark |

| TP304L |

SUS304L |

1.4307 |

X2CrNi18-9 |

0.030 |

17.5~19.5 |

8.0~10.0 |

|

Max:0.1 |

|

Straight/U

Bend |

| TP304L |

SUS304L |

1.4306 |

X2CrNi19-11 |

0.030 |

18.0~20.0 |

10.0~12.0 |

|

Max:0.11 |

|

Straight/U

Bend |

| TP304LN |

SUS304LN |

1.4311 |

X2CrNiN18-10 |

0.035 |

18.0~20.0 |

8.0~11.0 |

|

0.10~0.16 |

|

Straight/U

Bend |

| TP310S |

SUS310S |

1.4842 |

X6CrNi25-20 |

0.080 |

24.0~26.0 |

17.0~23.0 |

|

0.15~0.35 |

|

Straight/U

Bend |

| TP316L |

SUS316L |

1.4404 |

X2CrNiMo

17-12-2 |

0.035 |

16.0~18.0 |

10.0~15.0 |

2.00~3.00 |

|

|

Straight/U

Bend |

| TP316L |

SUS316L |

1.4436 |

X3CrNiMo

17-13-3 |

0.050 |

16.5~18.5 |

10.5~13.0 |

2.50~3.00 |

Max:0.11 |

|

Straight/U

Bend |

| TP316LN |

SUS316LN |

|

|

0.035 |

16.0~18.0 |

11.0~14.0 |

2.00~3.00 |

0.10~0.16 |

|

Straight/U

Bend |

| TP317L |

SUS317L |

1.4438 |

X2CrNiMo

18-15-4 |

0.035 |

18.0~20.0 |

11.0~15.0 |

3.00~4.00 |

|

|

Straight/U

Bend |

| TP321 |

SUS321 |

1.4541 |

X6CrNiTi18-10 |

0.080 |

17.0~20.0 |

9.00~13.0 |

|

|

Ti: 4*C~0.60 |

Straight/U

Bend |

| TP347 |

SUS347 |

1.4550 |

X6CrNiNb

19-10 |

0.080 |

17.0~20.0 |

9.00~13.0 |

|

|

Cb+Ta:10*C~1.00 |

Straight/U

Bend |

| N08904 |

904L |

1.4539 |

X1NiCrMoCu

25-20-5 |

0.020 |

19.0~23.0 |

23.0~28.0 |

4.0~5.0 |

|

Cu:1.00~2.00 |

Straight/U

Bend |

| S30815 |

Alloy 253

MA/F45 |

1.4835 |

|

0.05~

0.10 |

20.0~22.0 |

10.0~12.0 |

|

0.14~0.20 |

|

Straight/U

Bend |

| S31254 |

Alloy 254SMo |

1.4547 |

X1CrNiMoCuN

20-18-7 |

0.020 |

19.5~20.5 |

17.5~18.5 |

6.0~6.5 |

0.18~0.22 |

Cu:0.50~1.00 |

Straight/U

Bend | |

| |

|

高性能換熱管/冷凝管 (肥力鐵和馬氏體不鏽鋼) |

| ASTM/ASME |

JIS |

En |

DIN |

C |

Cr |

Ni |

Mo |

N |

Others |

Remark |

| TP410 |

SUS410 |

1.4006 |

X12Cr13 |

0.150 |

11.5~13.5 |

|

|

|

|

Straight/U

Bend |

| TP405 |

SUS405 |

|

|

0.080 |

11.5~14.5 |

MAX.0.50 |

|

|

Al:0.10~0.30 |

Straight/U

Bend |

| TP430 |

SUS430 |

1.4016 |

X6CrNiTi12 |

0.120 |

16.0~18.0 |

|

|

|

|

Straight/U

Bend |

| TP439 |

|

1.4510 |

X3CrTi17 |

0.070 |

17.0~19.0 |

MAX.0.50 |

|

0.04 |

Ti:0.20+4

(C+N)~1.10 |

Straight |

| S44400 |

QS192 |

1.4521 |

X2CrMo

Ti18-2 |

0.025 |

17.5~19.5 |

MAX.1.00 |

1.75~2.50 |

MAX.0.035 |

Ti+Cb:0.20+4

(C+N)~1.0 |

Straight | |

| |

|

高性能換熱管/冷凝管 (其他合金材料) |

| ASTM/ASME |

JIS |

En |

DIN |

C |

Cr |

Ni |

Mo |

N |

Others |

Remark |

| N10276 |

QA C276 |

2.4819 |

X12Cr13 |

0.010 |

14.5~16.5 |

Balance |

15.0~17.0 |

|

|

Straight/U

Bend |

| N06455 |

|

2.4610 |

|

0.010 |

14.0~18.0 |

Min.65 |

14.0~17.0 |

|

Ti: MAX.0.70 |

Straight/U

Bend |

| N06600 |

NCF600 |

|

NiCr15Fe |

0.150 |

14.0~17.0 |

Min.72 |

|

|

Cu:MAX.0.50 |

Straight/U

Bend |

| N06625 |

|

2.4856 |

|

|

20.0~23.0 |

Min.58 |

8.0~10.0 |

|

Cu:MAX.0.50 |

Straight |

| N04400 |

QA625 |

2.4360 |

NiCu30 |

0.300 |

17.5~19.5 |

Min.63 |

|

|

Cu:28.0~34.0 |

Straight/U

Bend |

| TI GR2 |

QA400 |

3.7035 |

|

0.100 |

|

|

|

0.030 |

Ti:Residual |

Straight/U

Bend |

| T5 |

|

|

|

0.150 |

4.0~6.0 |

|

0.45~0.65 |

|

|

Straight/U

Bend |

| T9 |

|

|

|

0.150 |

8.0~10.0 |

|

0.90~1.10 |

|

|

Straight/U

Bend |

| T11 |

|

|

|

0.05~0.15 |

1.00~1.50 |

|

0.44~0.65 |

|

|

Straight/U

Bend |

| T91 |

|

|

|

0.08~0.12 |

8.00~9.50 |

|

0.85~1.05 |

|

|

Straight/U

Bend | |

| |

|

| UNS |

抗拉強度

Min, Mpa |

屈服強度

Min, Mpa |

延伸率 in 2INCH.

Or 50mm Min, % |

硬度 Max,

HRB |

| TP304L |

485 |

170 |

35 |

90HRB |

| TP304L |

485 |

170 |

35 |

90HRB |

| TP304LN |

515 |

205 |

35 |

90HRB |

| TP310S |

515 |

205 |

35 |

90HRB |

| TP316L |

485 |

170 |

35 |

90HRB |

| TP316L |

485 |

170 |

35 |

90HRB |

| TP316LN |

515 |

205 |

35 |

90HRB |

| TP317L |

515 |

205 |

35 |

90HRB |

| TP321 |

515 |

205 |

35 |

90HRB |

| TP347 |

515 |

205 |

35 |

90HRB |

| N08904 |

490 |

216 |

35 |

90HRB |

| S30815 |

600 |

310 |

40 |

95HRB |

| S31254 |

675 |

310 |

35 |

96HRB |

| TP410 |

415 |

205 |

20 |

90HRB |

| TP405 |

415 |

205 |

20 |

90HRB |

| TP430 |

415 |

240 |

20 |

90HRB |

| TP439 |

415 |

205 |

20 |

|

| S44400 |

415 |

275 |

20 |

|

| N10276 |

690 |

283 |

40 |

|

| N06455 |

783 |

365 |

55 |

|

| N06600 |

500 |

180 |

35 |

185HB |

| N06625 |

760 |

345 |

30 |

220HB |

| N04400 |

480 |

170 |

35 |

|

| TI GR2 |

345 |

170Mpa≤σ0.2≤310Mp a |

24 |

|

| T5 |

415 |

205 |

30 |

89HRB |

| T9 |

415 |

205 |

30 |

89HRB |

| T91 |

585 |

415 |

20 |

25HRC | |

| |

|

ASTM A213/ASME SA213 Seamless ferritic and austenitic alloy steels boiler superheater, and heat-exchanger tubes

ASTM A249/ASME SA249 Welded austenitic steel boiler, superheater, heat-exchanger, and condenser tubes

ASTM A268/ ASME SA268 Seamless and welded ferritic/martensitic stainless steel tubing for general service

ASTM A688 Welded austenitic stainless steel feedwater heater tubes

ASTM A789, ASME SA789 Seamless and welded ferritic/austenitic stainless steel tubing for general service

ASTM A269, ASME SA269 Seamless and welded austenitic stainless steel tubing for general service

ASTM A803 Welded ferritic stainless steel feed water heater tubes

ASTM B163/ASME SB163 Seamless nickel and nickel alloy condenser and heat exchanger tubes

ASTM B165/ASME SB165 Nickel copper alloy (UNS N04400)* seamless pipe and tube

ASTM B167/ASME SB167 Nickel chromium iron alloys (UNS N06600, N06601, and N06690) seamless pipe

and tubes

ASTM B338/ASME SB338 Seamless and welded titanium and titanium alloy tubes for condensers and heat

Exchangers

ASTM B704/ASTM B705 Welded UNS N06625 and UNS N08825 alloy tubes / Nickel alloy (UNS N06625 AND

N08825) welded pipe

EN10216-5 Seamless steel tubes for pressure purposes - stainless steel tubes

DIN 17175 Seamless tubes of heat-resistant steels - technical conditions of delivery

DIN 17459 Seamless circular high-temperature austenitic steel tubes - technical delivery

Conditions

DIN 28179 Steel U-tubes for tubular heat exchangers - technical delivery conditions

DIN 28180 Seamless steeltubes for tubular heat exchangers - dimensions, dimensional deviations and

Materials

DIN28181 Welded steel tubes for tubularheat exchangers - dimensions, dimensional deviations and

Materials

GOST 11017 Steel seamless tubes for high pressure service - technical conditions

JIS G3455 Carbon steel pipes for high pressure service

JIS G3462 Alloy steel boiler and heat-exchanger tubes

JIS G3463 Stainless steel boiler and heat-exchanger tubes

JIS H4631 Titanium pipes and tubes for ordinary piping |

| |

|

|

|

|

|

|

U型弯管

U-管換熱器是由折流板和U型管束裝配在管殼中共同構成,為管殼式(列管式)換熱器一種,U形管束大大的增強了換熱面積和效率,高性能的U形管是確保設備正常運作的前提條件,高性能U形管對彎管設備提出了極高的要求,羅德鋼鐵通過CNC數控彎管系統,對管子的彎管半徑,減壁量以及圓度進行控制,並且在彎管后做去應力退火(以確保去除冷加工應力殘餘),做100%水壓試驗,出具彎管報告。

|

|

|

彎曲半徑: 1.5*OD(外徑)~1500毫米

當訂單要求管子的最小彎曲半徑小於1.5倍外徑時,必須和生產商協商一致。

直管生產最長長度(彎管前):35米

單腿長長度範圍: 最短1米,最長16.5米

注意:其他尺寸需要和生產商協商一致。

熱處理:彎管後進行去應力退火(彎管處加兩邊腿長的300毫米處)

包裝: 採用根據不同規格,彎曲半徑等設計的,薰蒸過的,適合海運運輸,牢固的實木木箱包裝,整管加套塑料薄膜,管端戴帽套,如客戶訂單內有特殊要求,嚴格恪守。 |

|

|

1.100% PMI檢測/SPECTRO 化學成分分析

2.100%尺寸檢驗&100%表面檢測

3.拉伸實驗,卷邊實驗,硬度試驗,反向壓扁實驗

4.彎管後100%水壓測試加100%無損檢測

5.根據客戶要求,檢查每隻U形管彎管後彎管處是否進行去應力退火,並提交彎管報告

注意: 所有檢測都需根據標準和測試結果提供檢測報告 |

| |

|

1.直線度測試

2.粗糙度測試

3.晶相分析

4.晶腐實驗

5.低溫衝擊實驗

6 .形管通球實驗

7.彎管處滲透實驗 |

|

a.材質單(根據EN10204/3.1或者EN10204 3.2要求提供材料檢測證書)

b.原材料質保書

c.根據標準和訂單要求的所有其他檢測報告

d. 熱處理報告

e.裝運前的裝運通知

f.質量保證函

g.彎管報告

h.彎管後熱處理報告 | |

| 【返回上一级】 |

|