|

|

|

|

|

| ก๖ Websited > Home > LSI Products |

|

|

|

|

|

|

Super Ferritic Stainless Steel Condenser Tubes

In Power Station Equipments,The choice of condenser tubes is vital to the investment and maintenance costs of the whole equipments. LSI are going to forecast the direction of the market of application of super ferritic stainless steel tubes in condensers and analysis the advantages of super ferritic stainless steel tubes compared with normal austenitic stainless steel tubes and titanium tubes from the aspects of chemical compositions,anti-corrosion capabilities, physical properties and mechanical properties of super ferritic stainless steel tubes.

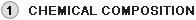

Chemical Composition:

S44660 super ferritic stainless steel tube is their high contents of Chromium and Molybdenum, and it has Titanium and niobium as stabilizing elements. The organization of material makes them with high strength properties, good elongation and low rate of work hardening.

|

|

|

|

UNS |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

N |

Others |

|

S44400 |

0.025 |

1.00 |

0.040 |

0.030 |

1.00 |

17.5~19.5 |

1.00 |

1.75~2.50 |

0.035 |

Ti+Cb: 0.20+4*(C+N)~0.80 |

|

S44660 |

0.030 |

1.00 |

0.040 |

0.030 |

1.00 |

25.0~28.0 |

1.00~3.50 |

3.00~4.00 |

0.04 |

Ti+Cb: 0.20~1.00 & 6*(C+N) min |

|

S44735 |

0.030 |

1.00 |

0.040 |

0.030 |

1.00 |

28.0-30.0 |

1.00 |

3.60-4.20 |

0.045 |

Ti+Cb: 0.20~1.00 & 6*(C+N) min | |

|

|

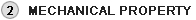

UNS |

Tensile Strength

Min, Mpa |

Yield Strength

Min, Mpa |

Elongation in 2INCH.

Or 50mm Min, % |

Hardness Max,

HRC |

|

S44400 |

415 |

275 |

20 |

95HRB |

|

S44660 |

585 |

450 |

20 |

25HRB |

|

S44735 |

515 |

415 |

18 |

100HRB | |

| |

|

ASTM A268/ ASME SA268 Seamless and welded ferritic/martensitic stainless steel tubing for general service

ASTM A688กกกกกก Welded austenitic stainless steel feedwater heater tubes

ASTM A803กกกกกก Welded ferritic stainless steel feed water heater tubes |

| |

|

|

| |

|

1.100% PMI / SPECTRO CHEMICAL ANALYSIS TESTS

2.100% DIMENSION TESTS & 100% VISUAL EXAMINATION

3.TENSION TEST, FLANGE TESTS, HARDNESS TEST, REVERSED FLATTENING TEST

4.100% HYDROSTATIC TEST AFTER BENDING PLUS 100% NON-DESTRUCTIVE TESTS

5.INTERGRANULAR CORROSION TEST BY LOT ACCORDING TO ASTM A763

6.PITTING RESISTANCE TEST ACCORDING TO ASTM G48 METHOD

7.RESIDUAL CHLORIDE TEST ACCORDING TO ASME SA803 |

| |

|

NOTES : ALL THE TESTS AND INSPECTION SHALL PROVIDE WITH REPORTS ACCORDING TO STANDARD AND TEST RESULTS. |

| |

|

1.STRAIGHTNESS TEST

2.ROUGHNESS TEST

3.CRYSTALLING PHASE ANALYSIS

4.INTERGRANULAR ATTACK TESTS

5.IMPACT ATTACK TEST UNDER LOW TEMPERATURE |

| |

|

1.MTC (MATERIAL TEST CERTIFICATION) ACCORDING TO EN10204/3.1 OR EN 10204/3.2

2.RAW MATERIAL CERTIFICATION

3.ALL THE TEST & INSPECTION REPORTS AS PER PO AND STANDARDS

4.HEAT TREATMENT REPORT

5.SHIPPING NOTIFICATION BEFORE SHIPMENT

6 .QUALITY WARRANTY LETTER. | |

| กพBackกฟ |

|